Bone Dry Unique: Everlasting Moisture Mitigation Concrete Sealer

Even when exposed to extreme weather conditions, the liquid waterproofing membrane continues to do its work, in contrast to other methods prone to expansion and contractions throughout climate fluctuations. When concrete flooring are uncovered to water, the durability/permanence of the construction lessens, thus increasing upkeep value. However, the poisonous results of water on concrete structures may be minimized or eliminated via waterproofing maintenance. Concrete waterproofing makes use of structural or chemical therapies to form impervious limitations that prevent water or some other liquid from eroding concrete buildings. While there are various approaches to concrete waterproofing coating, selecting the most effective process ensures the security and effectivity of the work. Tough 85-mil, pre-concrete pour, roll-on Underseal® Underslab waterproofing membrane/vapor barrier eliminates vapor and water transmission via concrete floors, to guard flooring finishes.

Why Liquid Rubber Is One Of The Best Waterproofing Paint For Concrete

- I've seen some adhesives eat right by way of waterproofing material.

- It is available in a sticky liquid emulsion that holds up on vertical concrete surfaces and may be utilized as a sprig or with a curler and trowel.

- One of the earliest was to paint the surface of the concrete in order that water couldn't be easily absorbed.

- With a rich history of success our product line was built to provide quite lots of merchandise and a full system method.

Another waterproofer as soon as told me that on one of his jobs the general contractor despatched in a laborer, after waterproofing was utilized, to break off kind ties on the within of a foundation. The laborer decided it might be easier to just pound the ties again into the wall. Every one of them punched via the waterproofing membrane on the other facet, which was already backfilled. Check the waterproofing producers literature for temperature limitations. You're most likely okay making use of waterproofing on a chilly day if you're working with a solvent-based material.

Waterproofing Concrete Makes A Sturdy Surface Extra Durable

If you're that one who wishes to spend extra on sustaining your concrete buildings, then this methodology is greatest suited for you. Polyurethane is made up of two elements, a base (polyol) and a reactor (isocyanide). When these two elements are mixed, a liquid coating is shaped, which is then used for waterproofing. This methodology could be conducted by semi-skilled professionals and requires minimal supervision. Besides, it’s faster to install, thus saves time and labor costs. Waterproofing a concrete flooring will ultimately lengthen its lifespan and reduce upkeep and restore costs.

Bone Dry Unique

It all adds up to lost money, wasted time, upset prospects and generally litigation. Pouring new concrete substrates is normally a lengthy course of that slows down building projects, creating a problem for home builders trying to keep residential building jobs on time and under finances. The last step will usually be testing the operate of the waterproofer. Each product will suggest the circumstances wanted for curing the product, but most will enable testing of the floor in a number of days. Concrete is a mix of some elements that, when combined, harden to kind a very hard, dense material.

Defending The Investment In Your Building

Here are some major security issues that go along with waterproofing. Because the waterproofer bonds with the concrete, it really strengthens it. This impact is minimal until the waterproofer is exceptionally thick, but the waterproofer лепило шпакловка за топлоизолация does form a sort of shell. Depending on the geographical location, some concrete installers will augment this waterproofing by laying builders’ plastic under the concrete. This prevents or reduces groundwater from seeping up via the concrete from under, plus it normally reduces the amount of concrete wanted.

Planning A Project?start Here

All the whereas, Bone Dry is difficult at work sealing porous areas of the slab and creating an impermeable barrier to forestall moisture from rising to the floor and damaging your home’s flooring. Concrete is fantastic materials and has been used in some form for millennia. Concrete is extremely durable, moldable, and comparatively easy to make use of.

Aside from bituminous coating, one can use a bituminous membrane to waterproof a concrete construction. The layers are greatest fitted to low-sloped roofs due to their glorious performance. PRECON is used as a blindside mebrane in vertical applications the place access to the positive side is limited. The membrane may additionally be used for horizontal functions for underslab waterproofing and vaporproofing. W. R. MEADOWS manufactures a complete line of concrete waterproofing and moisture control merchandise. When these products are used in mixture as a system, they guarantee that you've got got full management of moisture migration in your facility.

Polyurethane Waterproofing

This permeability can lead to structural points like mold, mildew, and weakening of the construction. This is why applying a reliable waterproofing paint for concrete is a necessity. And when it comes to the most effective waterproofing paint for concrete, Liquid Rubber tops the record. However, extra care is needed within the workmanship of concrete placement and finishing as properly as the selection of raw supplies whenever you depend on the concrete being waterproofed.

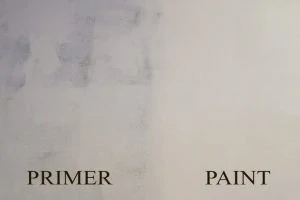

However, in some geographical areas, winter is definitely drier than summer season, so it is best to decide on a waterproofing product designed for the area. Therefore, the floor must be broom clean at a minimum, however it may also be pressure washed to realize the cleanest possible surface. This approach is common when sealing old concrete that may have years of buildup. In brief, the cleaner the concrete is, the higher job the waterproofing will do. In modern development, paint remains to be used occasionally, but it will typically be replaced by merchandise specifically designed for concrete, similar to concrete waterproofers.

How do you seal an old concrete slab?

- Strip any current sealer from the surface.

- Use an etching resolution to open up the concrete.

- Apply a thin coat of the sealer utilizing both a sprayer or curler.

- Leave the primary layer of sealer to dry.

- Apply a second coat of sealer in the different way to the primary.